Toll Free (Ontario): (877) 260-0987

Toronto & Central Ontario: (905) 823-9137

Southwestern Ontario: (519) 260-0987

Our company can provide designated substance assessments and exposure control programs.

Services

- Designated Substances

- Designated Substance Assessment

- Exposure Control

Acid Tanks

In Ontario, the Ministry of Labour has designated twelve substances as requiring their own separate legislation. These substances are as follows:

-

Acrylonitrile

-

Arsenic

-

Asbestos

-

Asbestos on Construction Projects

-

Benzene

-

Coke Oven Emissions

-

Ethylene Oxide

-

Isocyanates

-

Lead

-

Mercury

-

Silica

-

Vinyl Chloride

Hazardous Materials

A company requires a “Designated Substance Assessment” when one of the twelve designated substances is used at a workplace. The purpose of the assessment is to determine if employees are exposed to the designated substance and whether their health may be adversely affected.

An assessment involves a review of safety data sheets (SDS) and processes to determine what level of exposure could occur. Assessments often involve some exposure monitoring to get a better idea of the exposure levels present.

Once the assessment is complete, a formal report is prepared with recommendations and conclusions. The report must conclude whether employee health is likely to be affected or not. Where health is likely to be affected, a company must implement a “Designated Substance Exposure Control Program.”

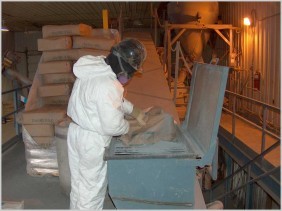

Silica Exposure

A “Designated Substance Exposure Control Program” is required when a “Designated Substance Exposure Assessment” determines that employee health may be adversely affected. The purpose of the program is to control employee exposure to the designated substance. Elements of the program typically include the following:

-

Personal protective equipment

-

Hygiene facilities

-

Engineering controls such as ventilation

-

Medical monitoring

-

Exposure monitoring

-

Employee training

-

Record keeping